The manual egg tray machine is the ideal piece of machinery for entrepreneurs looking to produce egg trays on a small scale or those who don’t have enough funds to purchase a fully-fledged egg tray-making machine. It is also suitable for poultry farmers who want to produce their own egg trays and earn some extra income on the side. When it comes to the manual egg tray making machine, the feeding, drying, collecting, and packaging processes are completed manually. This manual egg tray machine has a production capacity of up to 2000 egg trays per hour, which is enough to meet the needs of most small-scale businesses.

Raw Materials

The raw materials used to make egg trays are only water and all kinds of waste paper including old newspapers, books, magazines, A4s, used egg trays, etc. The ideal ratio of waste paper to water is 3:1. For example, if you have a 1000 egg trays per hour model, you will need to prepare 85kg of waste paper and 255kg of water. Don’t worry about egg tray making machine cost, Beston will offer you fair price.

Keep in mind that the egg tray making machine can be used to produce other products other than egg trays including apple trays, coffee cup trays, quail egg trays, seedling trays, industrial packaging trays, and shoe trays. This is done by changing the forming mold.

How to Make Egg Trays Using the Manual Egg Tray Machine

The egg tray making process involves four stages as outlined below:

Pulping

The waste paper is fed into the hydraulic pulper where it is mixed with water and made into a pulp. The pulp is then manually injected into the pulp beater where it is beaten into a fine and uniform pulp. The concentration of the pulp is also adjusted.

Molding

The adjusted pulp is then moved into the forming unit using a pulp pump. Under the power of a strong vacuum pump, the pulp is adsorbed onto the molds forming the egg trays. The formed egg trays are blown off the molds using an air compressor. Even accessories, Beston Group Co., Ltd. prefers to use famous brands.

Drying

There are three options available when it comes to drying the wet egg trays; natural drying, brick drying, and metal drying. The manual egg tray making machine typically uses the natural drying method since the number of egg trays produced is less than 2,000. Here, the workers manually place the wet egg trays outside to dry in the sun. Depending on the weather, the trays can take about four to five hours to dry. If the weather in your area doesn’t allow for natural drying or if you have high output requirements, you should consider choosing an automatic drying system such as the brick drying or metal drying system.

Packaging

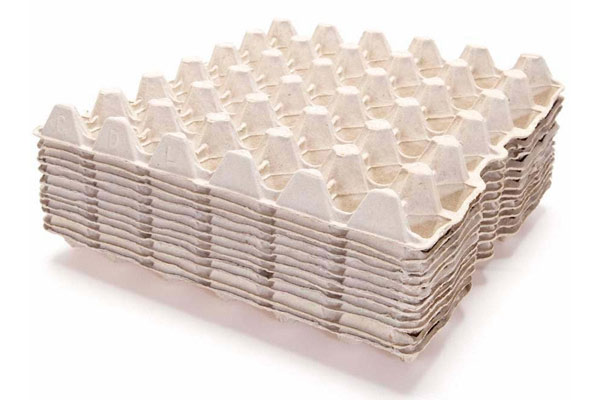

The workers then manually pick the dried egg trays then stack them and pack them ready for sale. To improve the speed and efficiency of your production, you can consider investing in a stacker and egg tray packing machine. These systems only require 1-2 workers to operate. If you want to see the explanation of the combination of pictures and text, please browse this website: https://bestonasia.com/how-to-make-egg-tray-from-waste-paper/.

Benefits of the Manual Egg Tray Making Machine

- Affordability

- Low power consumption

- Saves on space

- Wide range of applications