Only in the Japan, USA and EU about six million tons annually of scrap tire are produced. The large quantity of waste tires currently produced in the world will definitely rise in the future as the related to automotive industries increase.

The disposal of the scrap tires becomes an adverse environmental problem. The accumulation of the discarded waste tires results in environmental pollution. A huge fraction of the scrap tires is just dumped in areas where they represent hazards like accidental fires and diseases.

Rubbers aren’t biologically degradable, and this fact develops problems with their disposal. The effect of waste rubber on the environment can be reduced by recycling with energy recovery or material. Inquiry for the most reasonable tyre recycling machine price now.

Nonetheless, during processing and molding, rubber materials are cross-linked, and therefore they can’t be simply again softened and remolded by heating. For several years, the landfill was the major, practical means of overcoming the problem of waste tires.

What is pyrolysis?

Pyrolysis refers to a thermochemical decomposition of organic material at elevated temperatures without oxygen (or any halogen). It involves an instantaneous change of physical phase and chemical composition and is irreversible. Pyrolysis is also called thermal cracking, thermolysis, cracking, depolymerization, etc.

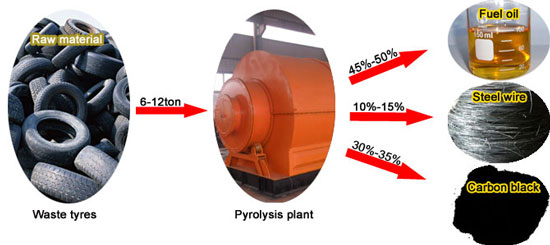

Waste tyre pyrolysis plant refers to a process of converting various waste tires into industrial fuels such as tire pyrolysis oil, steel wire, carbon black, and hydrocarbon gas.

The process involves subjecting tire to the elevated temperature of 400-450 degree Celsius, in with limited or no oxygen.

During pyrolysis tire disintegrates into smaller molecules of pyrolysis gas, pyrolysis oil, carbon black and steel wire. Pyrolysis is the best way of recycling massive amounts of tires.

Working Process of Waste Tyre Oil Plant

1. Feed raw materials

The raw material can be waste rubber /waste plastic/waste tire. Always feed by an auto feeder.

2. Pyrolysis

Include a catalyst and reactor room. Heat the reactor by wood /coal /oil/natural gas. This part will generate high-temperature oil gas, then oil-gas flow into the subsequent system.

3. Condensing

Oil gas come out from the catalyst and reactor chamber then cooling down in this section. The condensing system includes an oil-water separator, condenser pipe, waste gas condenser and horizontal condenser. This will make the oil produce to the maximum.

4. Waste gas recovery

This part majorly deal with the gas which can’t be condensed. The entire process is very steady and great efficiency.

5. Discharge

After the finished oil yield, reactor temperature can be cooled down. When the temperature reduces to 400, then carbon black can be released automatically through an anticlockwise rotate the reactor.

The carbon black eventually will drop into the slag pool and then uses screw conveyor to clean a slag pool. After releasing the carbon black, steel wire can be produced.

Advantages of Waste Tyre Recycling Plant

1. Energy-saving -By the additional gas recycling system, the gas which cannot be condensed will be recycled to a burning room. It can substitute the fuel material to heat the reactor that will lower extra fuel consumption.

2. Safe -The machine is fitted with mature safety devices, like alarm for over pressure and temperature, extra gas recycling system, auto pressure releasing system, and firefighting device, that’ll guarantee 100 percent safety in the pyrolysis process.

3. Environment-friendly -In the dedusting system, 3 steps (ceramic ring filter, water spray, washing chamber) are used to dedust the additional gas, and over 95 percent of the dust would be removed. The produced gas is pollution-free and can be released into the air directly.

The tire pyrolysis oil can be largely used as fuel oil in industries like iron and steel and boiler factories, power, ceramics, or chemical industries, etc.

If refined further to gasoline or diesel, it can be directly used in generators and various engines. With the demand of oil rising, the tyre pyrolysis oil market price will certainly become higher and higher in the future.

The steel wire and carbon black also have a broad range of applications that can develop more benefits for you.